ADAS Calibration

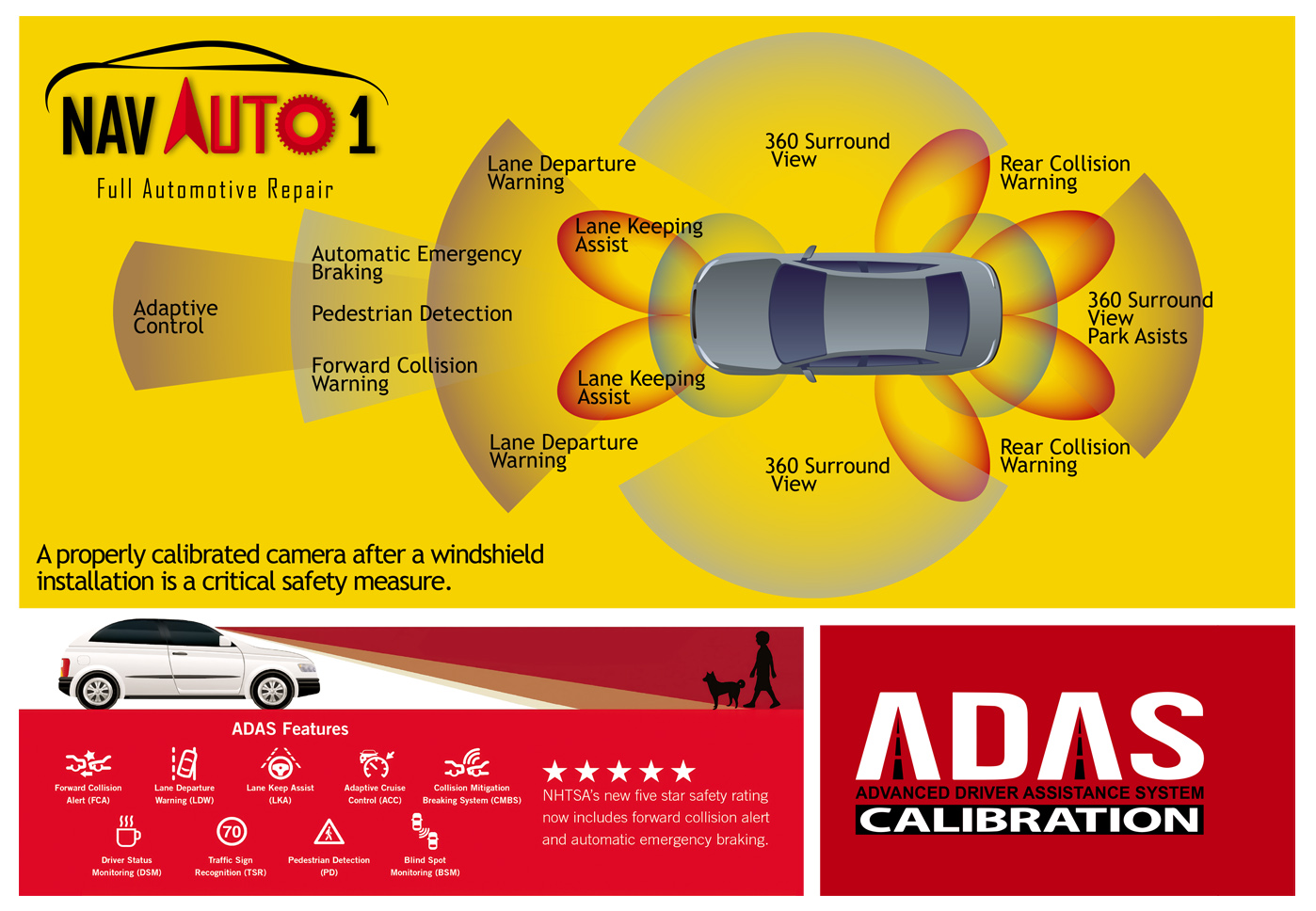

Nav Auto1, introduction to ADAS where all calibration is done in our facility, or we can come to you or your body shop! Increasing numbers of new cars are equipped with Advanced Driver Assistance Systems (ADAS). Some of the more common ones include:

- Forward collision warning

- Automatic emergency braking

- Adaptive cruise control

- Lane departure warning

- Lane-keeping assist

- Blind-spot monitoring

- Rear cross-track alert

- Parking assist/self-parking

- Adaptive headlights that steer with the vehicle

- Automatic headlight high-beam activation and dimming

To do their jobs, ADAS relies on inputs from various sensors that allow the systems to “see” what is happening around the automobile. The most common are the camera, radar, and ultrasonic sensors. Steering sensors are also used to help determine the direction of vehicle travel. Some systems use information from a single type of sensor, but others combine information from multiple sensors – a process called sensor fusion – to obtain a more accurate “view” of the situation.

Most ADAS sensors are very precisely aimed and require calibration if their positions are disturbed in any way. Misaimed sensors often result from collisions – even a minor fender bender can knock ADAS sensors out of alignment. However, calibration can also be required as a byproduct of common car service work such as windshield replacement, suspension repair, or wheel alignment.

Failure to calibrate a sensor when necessary, can result in faulty information that will cause ADAS to operate improperly or not at all. Faulty sensor input can cause:

- A warning light or message on the instrument panel

- A diagnostic trouble code (DTC) being stored in the vehicle’s computer memory

- Steering wheel vibration

- Vehicle steering pull

- Increased steering effort

Problems like these can cause a driver to lose trust in a car’s ability to provide safe transportation. ADAS failures may also raise questions about the quality of an auto repair shop’s work.

Sensor Types

The most common types of ADAS sensors are cameras, radar units, ultrasonic transmitters, and steering angle sensors. Here is more information about each.

Front-Facing Camera Sensors

Many vehicles are equipped with front-facing camera sensors. These sensors are commonly used for automatic emergency braking, adaptive cruise control, lane departure warning, lane-keeping assist, and automatic headlight high-beam activation and dimming.

Because cameras are optical devices that must “see” the road, it is usually easy to identify when a car is equipped with this type of sensor. Many camera sensors mount against the inside of the windshield as part of an assembly integrated with the rearview mirror; others attach to the inside of the roof – either directly or as part of a mirror housing. Some automakers, including Subaru and Land Rover, use dual cameras spaced apart to provide enhanced depth perception.

The high-definition image receptors used in camera sensors are different from those found in other digital camera applications. What makes ADAS camera sensors unique is the high-powered microprocessors and advanced data processing algorithms built into the assembly. These components turn the constantly changing analog image the camera sees into digital information that ADAS can use to control various safety-critical systems.

Camera sensors “see” the world through the windshield and are designed for specific light transmission rates through the glass that has minimal imperfections and distortion. A problem in any of these areas can interfere with a sensor’s ability to provide accurate information. Thus, many automakers specify that only an Original Equipment Manufacturer (OEM) windshield is used if a replacement is necessary on a car with a camera sensor. In fact, some car dealers will refuse to calibrate a camera sensor on a car that has an aftermarket windshield installed.

Other Camera Sensors

Some newer cars have 360-degree “around-view” camera systems that use several small cameras at the front, rear, and sides of the vehicle to display an overhead view of the immediate area around the vehicle. These are simpler and lower-resolution cameras than those used for ADAS, although they also require calibration. The cameras are usually located in the front bumper or grille, under the side mirrors, and in the trunk lid or liftgate. The computer controlling the system “stitches” the multiple images together to provide a smooth overall view displayed on the infotainment screen in the dash.

Front-Facing Radar Sensors

Adaptive cruise control, forward collision warning, and automatic emergency braking are the ADAS most commonly associated with front-facing radar sensors. The millimeter-wave radar sensors used on vehicles transmit a high-frequency radio signal that reacts off objects and returns to the sensor. The time it takes to receive a return signal is used to calculate the car’s distance from an object.

Radar sensors are usually mounted in or behind the front bumper or grille. In a few cases, the radar sensor is mounted in the front-facing camera housing ahead of the rearview mirror. Radio waves can pass through glass and plastic bumper covers or grill materials, and the sensor usually has a cover to protect it from stones and other road debris. While many radar sensors are centrally mounted, others are set to one side of the automobile, which affects the calibration process.

Because they are sometimes hidden, determining whether a vehicle has a radar sensor can be more difficult than identifying a camera sensor’s presence. If an external visual inspection does not indicate a sensor’s presence, opening the hood could reveal one. Another method is to check for adaptive cruise control switches inside the car (usually on the steering wheel) or a warning light for an automatic emergency braking and/or an adaptive cruise control system that illuminates on the dash as a test when the car is first started.

Other Radar Sensors

Some rear collision warning and blind-spot monitoring systems use small radar sensors mounted under the side view mirrors, rear bumper cover, or even in the taillights. Bumper and taillight-mounted sensors may also provide rear cross-track alerts when backing out of parking spaces.

To prevent potential interference, most auto manufacturers do not allow repairs to areas of bumper covers that are in front of radar sensors. They also recommend using only OEM covers to ensure that the materials used will not interfere with the sensor signals. Excessive bumper cover paint thickness can also be a problem on some vehicles, and automakers advise against placing bumper stickers anywhere near the radar sensors.

Ultrasonic Sensors

Ultrasonic sensors are primarily used for parking assist and self-parking systems. These sensors are installed in the front and/or rear bumper covers where they use reflected high-frequency sound waves to detect people, cars, and other objects in close proximity to the vehicle. Sensors of this type on the sides of cars are used in some self-parking systems and may serve as supplemental sensors in blind-spot monitoring systems.

Ultrasonic ADAS sensors do not require calibration. However, they are designed to be in exact positions in the bumper cover or anywhere else they are mounted. For this reason, some automakers do not approve the use of aftermarket, reconditioned, or recycled body parts, which may be distorted or lack pre-drilled holes in the proper locations for mounting the sensors. Although most ultrasonic sensors broadcast a symmetrical circular sound pattern, some generate an asymmetrical oval pattern, which requires that they be mounted with a specific orientation to work properly.

Steering Angle Sensors

Steering angle sensors are used in lane departure warning, lane-keeping, and adaptive headlight ADAS. The information they provide is also used for other safety and performance-related systems such as electronic stability control and adaptive suspensions. These sensors are usually built into the steering column and measure the degree of steering wheel rotation.

Sensor Calibration

ADAS sensor calibration is required whenever a sensor’s aiming is disturbed in any way. This can occur in a collision, even a minor fender bender, or be a byproduct of common service work such as windshield replacement, suspension repairs, or wheel alignment. Calibration is also called for whenever a sensor or its mounting bracket is removed and replaced, there is a change in tire size, a front airbag deploys and deflects off the windshield, or repairs are made to a car roof that has a sensor bracket mounted to it. Finally, sensor calibration is necessary when a related DTC in the car’s computer memory or an automaker releases a technical service bulletin with instructions that calibration is done as part of another repair.

Sensor replacement and calibration are frequently part of collision repairs. Automakers recommend that body shops perform a complete diagnostic scan on every vehicle before repairs are begun and then again after the job is complete. Doing so will help the auto body shop better understand the scope of any problems before work starts. Then confirm that all issues have been resolved, ADAS sensor calibrations are complete, and the vehicle control systems are communicating properly before the car is returned to the customer.Calibrating ADAS sensors is a precise process that is frequently complex and time-consuming. Some sensors can be calibrated in a repair shop, others require that a vehicle be driven, and many sensors call for both procedures. The time involved can vary from 25 minutes to 65 or more, depending on the specific calibration requirements. When necessary, this additional labor adds to the cost of repairs.

Shop Preparation

Many auto repair shops and windshield installers currently send cars to the dealer when the ADAS sensor calibration is required because of the challenges involved. Independent service providers that want to perform sensor calibrations must make a significant investment in these necessary tools:

- Service information that describes the equipment and procedures required to calibrate the ADAS sensors on any given year, make, and vehicle model. This information may be available from the aftermarket but sometimes must be obtained from the auto manufacturer. ADAS sensor calibration requirements can be determined by performing a brand search. Both options incur a cost for the servicing repair shop.

- A car computer scan tool that supports ADAS sensor calibration. Factory scan tools can handle the necessary operations for all vehicles and sensors from a specific automaker. Aftermarket scan tool capabilities vary widely, but certain devices will work with vehicles and sensors from several different automakers. Special tools designed exclusively for ADAS sensor alignment are also available, but the extent of vehicle coverage varies as with aftermarket scan tools.

- A large, level, paved, an indoor area with non-glare lighting and a backdrop free from clutter (camera sensors) and metallic objects (radar sensors) that can interfere with calibration. Honda, for example, species an open area that is 13 feet wide, 5 feet high, and extends at least 23 feet in front of the car. The Lexus radar calibration process (done outdoors) requires a large, level open road at least 32 feet long and 45 feet wide ahead of the car.

- A wheel alignment rack. Many automobile manufacturers require or recommend that a four-wheel alignment be performed before ADAS sensor calibration. This ensures that the vehicle thrust line, an imaginary centerline drawn lengthwise through the car, points straight down the road when the steering wheel is centered. ADAS sensors are then calibrated to be in alignment with the thrust line. Wheel alignment equipment is now becoming available with built-in ADAS calibration capabilities, although a static and/or dynamic aiming process (see below) may still be required.

Vehicle Preparation

Before calibrating an ADAS sensor, a vehicle must be prepared as specified by the automaker. Some of the common requirements include:

- No unnecessary heavy items in car or trunk

- Tires inflated to recommended pressures

- Front and rear vehicle ride height within specifications

- Fuel tank full

- Windshield clean in front of the camera sensor (where applicable)

- Protective cover removed from the radar sensor (where applicable)

- Four-wheel alignment performed (where specified)

Calibration Methods

There are two forms of ADAS calibration, static and dynamic. General descriptions of these processes are provided below, but the exact procedures vary significantly from one vehicle make and model to the next. In all cases, the automaker’s specified procedures and instructions must be precisely followed.

In-Shop (Static) Calibration

Static sensor calibration begins with establishing the vehicle thrust line. Automakers specify a variety of manual measuring methods and special tools to perform this part of the process. The tools attach to or are aligned with the front and rear wheel hubs in many cases. Laser projectors are often built into tools to help ensure perfect alignment.

Next, one or more special aiming targets are positioned in precise locations relative to the thrust line and sensor. The targets must be at a specified height, and many are designed for use with special adjustable mounting stands. Where a sensor is offset from the car’s centerline, the targets must be correspondingly offset as well. While at least one vehicle uses a target placed on the hood, most target locations are 10 to 20 feet from the vehicle.

Camera aiming targets are usually black and white patterned images purchased or, in some cases, can be downloaded from service information sites. Targets that have been downloaded may have to be resized using a copy machine. With some vehicles, the target must be lighted in a specific manner to ensure proper calibration.

Radar targets may have patterns that appear similar to cameras but include metal elements that reflect radio waves to the sensor. Another type of radar target is a metal cone whose open end is positioned facing the vehicle to reflect radio waves to the sensor.